One Earth® Filter Media

BIODEGRADABLE TEA BAG FILTER MATERIAL MANUFACTURER

One Earth® filter media has full taste neutrality, is biodegradable, compostable, and translucent. The filter media shapes easily into pyramid, round or single chamber compostable tea bags.

A Great Cup of Tea in Less Time

Optimized Fabric Breath-ability

Optimized fabric breath-ability provides an immediate water contact and diffusion with the tea leaves, without any “ballooning effect.” Infusion time is optimized.

Translucence & Full Taste Neutrality

Our filter media allows for enhanced visibility of the tea and other flavored components. Filter becomes clear during infusion.

One Earth® fabrics minimize tea flavor retention, unlike paper fabric, which absorbs and retains over five times its weight in water.

Easy to Process

One Earth® fabrics work on standard high-speed packaging equipment at reduced temperatures for energy savings. Seal on most standard heat sealing machines with no modifications. Seal on ultrasonic welding machines without major adjustments.

Allergen Free

One Earth® does not use a chemical treatment during the manufacturing process. All components meet FDA requirements for Food and Beverage. One Earth® is allergy and gluten free.

Biodegradable Issue and Solution

ISSUE

Paper tea bags are made of 15 to 35% of non-biodegradable residual plastics and chemical binders. Pyramid tea bags are made of Nylon fabric which is also non-biodegradable.

SOLUTION

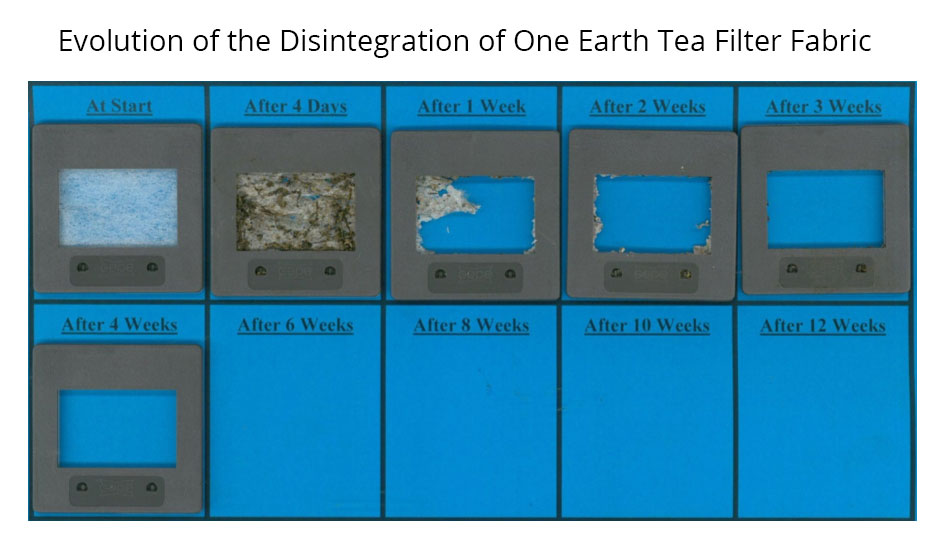

The One Earth® product line is certified compostable in 14-21 days. View the evolution of disintegration of our tea filter fabric below.